Take The DOSOMAT Challenge

Have you seen a WALDNER DOSOMAT in operation? Now’s the perfect time!

Within the next few weeks, DOSOMAT cup filling machines will be completed at the Waldner factory in Wangen, Germany. PTI and Waldner invite you to visit the factory to see these high performance machines in operation. Availability dates for some machines are limited, and certain machines will be available for longer time periods. Details are outlined below.

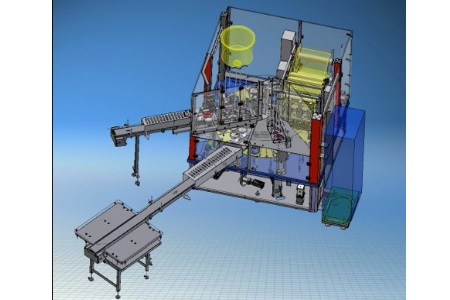

DOSOMAT 12.4 with carton erector and packer

Rotary machine in “Hygienic Design” for filling coffee drinks in plastic cups.

Visit dates: February 2 – 13

- Sterilization, filling and closing of up to 7,500 cups per hour

- State-of-the-art machine controls by Schneider Electric “PacDrive 3”

- Closure with aluminum sealing lid and plastic snap-on lid

- Cup infeed with WALDNER cassette system

- Cup sterilization with H2O2

- Lid sterilization with UVC-irradiation

- Laminar airflow cabinet

- Fully automated cleaning and sterilization of dosing valves and product pipes

- Highly-flexible integrated WALDNER Packer with Pick-and-Place-System for direct loading of cups in cardboard trays

- Upstream WALDNER carton erector and case packer

DOSOMAT 10.3 – SuperLock

Rotary machine with evacuation and gas flushing for filling paté Closure is a special snap-on lid with twist cap

Available for long term visit dates

- Product infeed via special hopper with agitator

- Closed chamber for evacuation of cup head space and subsequent flushing with protective gas. Residual oxygen content: < 0.2%

- Up to 17 cycles/min. with vacuum and gas

- Closure: sealing from roll stock with integrated sealing cutting unit.

- Features special “SuperLock” snap-on lid with twist cap

- Two formats for running different cup sizes (Ø 70 + Ø 95 mm)

DOSOMAT 1.2 – Compact, flexible, ultra-modern

Rotary machine with most advanced design for small and medium capacities

Available for long term visit dates

- State-of-the-art machine controls and visualization by Schneider Electric “PacDrive 3”

- Designed for high flexibility and quick format change

- Tool-less changeover of sealing heads

- Maximum capacity: 50-60 cycles/min.

- Piston dosing system with tappet valves in CIP for filling plastic cups with several different dairy products

- Closure with plastic or aluminum sealing lids

- Modem for remote services

DOSOMAT 12.3 – One machine for all products

Rotary machine for filling dairy products with large filling volumes

Visit dates up to February 25

- Filling plastic cups with sizes between 450g and 2.5 kg, with and without handle.

- Capacity: up to 6,500 kg./hour

- Dosing system with special filling valves for liquid and pasty products.

- Special infeed system via conveyor belt including synchronizing of already filled cups into the DOSOMAT for subsequent sealing and application of snap-on lidding.

- Closure: sealing from roll stock, with print-registered film and snap-on lid

- Fully automatic cleaning of dosing system and product pipes (CIP) through separate WALDNER CIP trolley

- Inkjet coding station installed on discharge conveyor.

About PTI Packaging Systems

PTI Packaging Systems specializes in packaging machinery solutions for filling and sealing pouches, sachets, stick packs, cups and trays. Applications range from products in individual portion packs up to bulk size bags. Solutions include retort sterilization and integrated downstream equipment. PTI’s supplier partners produce exceptional equipment that provides the performance, reliability, flexibility and versatility customers need. Our team can also bring new and creative package designs to market. We support brand differentiation and help make new packaging ideas and innovations a reality. For more information, visit www.ptipacktech.com.

Source: PTI - Packaging Technologies & Inspection