Quick Breakfast Foods

By Susan McKinney, Contributing Editor

From Food Product Design Magazine

Table of Contents

Up and at'em

Flour power

Rising to the challenge

Chemical leaveners

Sugar, sugar

Fatty, fatty

The bakers rack

Sweet starts

Good and fruity

The eggs come first

Breakfast meats

Putting it all together

Hearty, sit-down family breakfasts during rushed mornings are a thing of the past. What and where do rushed consumers eat breakfast? They eat convenience foods at home, behind the wheel, at the desk, in work cafeterias or from vending machines. But they still want familiar breakfast foods that deliver on taste, combined with ease of preparation and virtually no clean-up.

Up and at 'em

Consumers looking for breakfast on the run have a wide array of products from which to choose. Some may select ready-made products from the freezer or the pantry. Before the coffee is finished brewing they can microwave traditional entrees such as pancakes and bacon, scrambled eggs, potatoes and sausage, plus hand-held combination meals, breakfast sandwiches and burritos. Chocolate chips, fruits, whole wheat and multi-grains add variety to frozen pancakes and waffles. Shelf-stable products such as toaster pastries and fruit-filled and granola-type bars have increased market share by appealing to adults as well as kids.

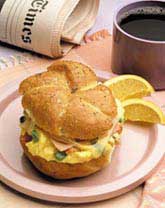

For those who use their daily commute for breakfast, the combination of driving plus breakfast is a limiting factor for responsible drivers. Requirements in order of priority are: easy to eat with one hand, doesn't drip, tastes good. This is one of the few times where taste isn't necessarily first for consumers. Common commuter choices include bagels, English muffins, donuts, cinnamon rolls, muffins, Danish or breakfast sandwiches.

Frozen breakfast sandwiches are sold in most retail channels. These contain eggs, cheese and meat served on biscuits, English muffins, croissants, tortillas or bagels. In the fast-food world, McDonald's pioneered the first quick-serve breakfast sandwich, served on an English muffin. Burger King followed with a croissant breakfast sandwich and Hardee's introduced their breakfast sandwich on a biscuit. A November 1999 survey by the Washington, D.C.-based National Restaurant Association reported that biscuits topped the list of breads sold at quick-serve restaurants in 1998. Now, bagels are another popular bread choice.

Two traditional sit-down breakfast foods have moved into the fast lane. McDonald's introduced their first breakfast Happy Meal, with mini pancakes and syrup and Burger King quickly followed with mini pancakes, described as "dip and go" for consumers on the move.

Today's quick breakfasts cover a wide variety of flour-based foods (bagels, biscuits, croissants, muffins, pancakes, waffles, donuts, Danish pastries and cinnamon rolls), eggs, and meats. The secret to success is finding the right combination of ingredients.

Flour power

Quick breakfasts contain a large proportion of grain-based foods, most consisting mainly of wheat flour. Three wheat classes are grown for food use: hard, soft and durum wheat. Of these, hard and soft wheat flours are used in the baked goods that make up so many breakfasts. All varieties of refined wheat flour require enrichment with nutrients lost during milling off the bran, (thiamine, niacin, riboflavin and iron) and, more recently, fortification of folic acid at specified levels. These flours are available in whole wheat, refined or white, which can be bleached or unbleached.

Flour color and maturity are important in all baked goods. When freshly milled, flour contains naturally occurring pigments, primarily xanthophylls and carotenoids, imparting a yellow color. Natural oxidation, with time, removes the yellow color, but chemical oxidizing agents, such as chlorine dioxide and nitrosyl chloride, speed the process. Chemical maturing agents contribute increased volume, improved mixing tolerances and machine ability. Azodicarbonamide (ADA), potassium bromate and proprietary blends containing ascorbic acid are the most commonly used maturing agents.

Hard wheat flour, or bread flour, is used primarily for yeast-leavened products such as bagels, croissants, English muffins, Danish sweet rolls, cinnamon rolls (except refrigerated doughs) and glazed, Bismarck and filled donuts. The protein content of bread flours ranges from 12% to 14%. Protein content alone does not guarantee high-quality bread flour, however. Flour contains two proteins of importance to yeast-leavened doughs - glutenin and gliaden. When these are mixed with water, gluten forms. This creates an elastic, extensible matrix; high-quality gluten entraps large amounts of the carbon dioxide produced by yeast fermentation. Additionally, greater water absorption in bread flour results in better dough yield.

The protein content of soft wheat flours ranges from 8% to 10%. The lower protein level produces a cell structure that provides good mouthfeel and a less chewy texture in chemically leavened baked goods. Examples of soft-wheat-flour breakfast uses include biscuits, muffins, toaster pastries and cake donuts. Cookie and cake flours are also made of soft wheat. Cake flours have a lower ash content and smaller particle size, and are treated with chlorine to lower pH, which improves cake properties. This type of flour is increasingly used to formulate commercially made muffins as well.

Rising to the challenge

Unleavened medium- to high-moisture baked goods are dense and heavy, with virtually no cell structure. Most flour-based breakfast foods require leavening agents to produce the desired cell structure. Formulations of leavened baked goods contain many of the same ingredients, but vary widely in proportion and processing techniques.

Three types of leavening agents can be used - water, yeast and chemicals. Most formulations contain water, which when heated, forms steam and expands. However, water does not contribute significant amounts of leavening in most baked goods - cream puffs and popovers are exceptions - and most products require additional leavening, either with yeast or chemical leaveners.

Depending on process, cost and desired effect in the finished product, various forms of yeast may be used - compressed, fresh in cake or crumbled form, liquid cream yeast, or active dry yeast. Yeast produces carbon dioxide as a byproduct of carbohydrate fermentation. Because monosaccharides such as glucose, fructose and mannose provide the most easily assimilated yeast energy source, malt or alpha-amylase can be added to aid in starch breakdown. Depending on the finished flavor or desired proof times, an additional carbohydrate source may also be added.

Using certain ingredients in excess - such as the salt that is added for flavor - may limit yeast growth. Extra nitrogen, as part of a dough improver, can be added to ensure optimum yeast growth. This produces the necessary carbon dioxide to yield oven spring, which is the sudden expansion of dough by about one-third its original volume during the early baking stages. If the gluten network formed is not sufficiently elastic, however, the increased volume is not maintained.

Doughs are traditionally proofed, or allowed to ferment, twice. This not only results in an increase in dough volume, but also develops characteristic fermented-yeast flavors. No-time doughs are only proofed once. The finished products are similar in quality to traditional doughs, but increased levels of dough conditioners and yeast are required.

Chemical leaveners

Developing foods with chemical leavening systems doesn't have to be a trial-and-error process. Suppliers of leavening acids are well known for providing personalized technical support. Chemical leavening agents produce carbon dioxide by combining acids and bases, which, when in solution, produce carbon dioxide and water. Sodium bicarbonate, or baking soda, acts as the base in the high-moisture products typically seen at breakfast. Ammonium bicarbonate can only be used in low-moisture applications such as toaster pastries and breakfast bars, since the ammonia flavor persists at high moistures. For low-sodium applications, potassium bicarbonate may be used, but about 19% more is needed to gain the same effect as soda. Acids commonly used include monocalcium phosphate (MCP), sodium acid pyrophosphate (SAPP), sodium aluminum phosphate (SALP) and dicalcium phosphate (DCP). Anhydrous monocalcium phosphate (AMCP) is sold with a coating that slows its rate of reaction. Other common leavening acids are sodium aluminum sulfate (SAS), monopotassium tartrate (cream of tartar), and glucono-delta-lactone (GDL). If the pH of the flour is low enough, it too can function as a minor leavening acid.

Leavening acids vary in their neutralizing value (how much is added to neutralize the soda), rate of reaction and reaction temperature. The reactivity of the acids, or dough reaction rate (DRR), is mainly a function of solubility in water at different temperatures. Solubility is influenced not only by chemical composition, but by factors such as particle size, and any coatings or encapsulation techniques used. Dough temperature and rate of temperature change also affect solubility. Reaction rate may also be influenced by the addition of other ingredients - sugar and milk (due to calcium), for example, can slow the rate.

The leavening reaction typically occurs over a period of time rather than all at once, but acids that react mostly at the batter or dough stage are generally categorized as "fast-acting" vs. those that function during baking, frying or griddle cooking. Often, leaveners are used in combination to achieve a specific effect. For example, cake doughnuts usually have a combination of a fast-acting SAPP and a slower leavener such as SALP or GDL to permit rapid expansion when the batter hits the hot fryer oil.

Reaction rate affects the finished product's grain, volume and texture. The goal of the product developer is to balance the system so that none of the acid or base remains in the baked good. Residual soda causes a soapy flavor and yellowing of light-colored products. Excess phosphate causes metallic off-flavors and an unusual squeaky-teeth feeling.

Leavening reactions can be inhibited to add convenience in the form of prepared doughs. Acids or bases, depending on the formulation, are encapsulated using fats with specific melting points that keep the leaveners from going into solution until they reach a certain temperature. Refrigerated biscuits and breakfast rolls, for example, are convenience foods made possible by encapsulated leavening systems.

Sugar, sugar

Sweet goods such as muffins and pastries require some form of sweetener. Sucrose, a non-reducing disaccharide refined from sugar cane or beets, provides a clean sweetness in baked goods with no off-flavors. Liquid sucrose is available, and is used primarily for yeast-leavened doughs. Sucrose is the gold standard of sweeteners, but is losing favor in bakeries because of its high price. Additional deterrents to its use are difficulty in transport and storage, sanitation issues and increased production costs. This has led to the use of alternate sweeteners in many applications.

Invert sugar is still popular in bakeries. It is made by boiling sucrose with a dilute acid, breaking the sucrose into its constituent monomers, glucose and fructose. At 75% solids, the invert syrup is as sweet as sucrose. Invert syrup is hydroscopic and resists crystallization, and is used where moisture absorption and retention are important, such as in muffins and icings. It is also brushed on Danish pastries after baking to help seal in moisture.

Corn syrup is made from waxy maize cornstarch via either acid or enzyme hydrolysis. Corn syrup can be completely hydrolyzed to glucose, but typical hydrolysis forms a mixture of maltodextrins, polysaccharides, maltose, dextrins and dextrose. Degree of hydrolysis is measured in dextrose equivalents, or DE. The lower the DE, the less sweet and more starch-like, and the higher the DE, the sweeter and thinner the syrup. Enzyme-converted syrups tend to have a cleaner flavor, are sweeter and remain free-flowing slightly above ambient temperature as compared to acid-hydrolyzed syrup. Corn syrup, especially the lower DE forms, can help control crystallization, an important formulation consideration for icings and glazes. All corn syrups are hydroscopic, which helps retain moisture, thus extending shelf life.

High-fructose corn syrup (HFCS) is sweeter than sucrose and is in plentiful supply. HFCS is easier to transport for bakery and fruit-filling operations, and is hydroscopic, helping retain moisture to extend shelf life. Like corn syrup, HFCS is produced from waxy maize cornstarch, but is reduced to fructose and some glucose by the enzyme glucose isomerase. HFCS varies in fructose content from 42% to 90%. The 42% product is most often used because the balance of fructose/glucose most closely simulates sucrose.

Fructose, lactose, maltose and dextrose are all reducing sugars so they react with amino acids when heated, forming Maillard reaction compounds that give a brown color and characteristic baked flavors and aromas. Flour can act as the source of amino acids, and milk proteins in the form of NFDM or whey can provide additional protein, as well as lactose, for increased browning.

Honey has some great functional properties as a sweetener, but due to its high cost it is primarily used for flavoring. It contains 41% fructose, 34% dextrose, 2% sucrose and 18% moisture.

Fatty fatty 2x4

Fat is used in baked goods for tenderization of crumb, flavor, extending shelf life, and entrapping air in specific applications. Fat and oil selection is specific to each application and to the finished-product requirements.

Plastic fats, or shortenings, are made from RBD (refined, bleached and deodorized) vegetable oils that are hydrogenated or mixed with hard fats or fat fractions, depending on application. General-purpose shortenings are designed to be used in a wide variety of applications ranging from biscuits to muffins.

Bakery fats are sometimes manufactured with added emulsifiers. High-emulsifier shortenings help evenly distribute shortening in the aqueous phase of a baked good. In most high-moisture baked goods, higher fat levels plus emulsifiers reduce starch retrogradation and staling and often increase aeration.

High-emulsifier shortenings are used in breakfast products for icings, sweet goods (cinnamon rolls, coffee cakes) and are a good shortening choice for most breakfast baked goods, with the exception of frying oils. Due to their resistance to oxidation, high-stability shortenings are used for frying and in products that require a long shelf life. Lard, although currently out of favor because of health concerns about animal fats, helps generate the tender texture typical of pie crusts.

Butter provides functionality as a fat, but is primarily used for flavor in baked goods due to its high cost. Instead of butter, several types of margarines are used in breakfast products. Margarines, which contain the same level of fat as butter, are often colored to various yellow hues and contain natural and/or artificial butter flavor. Margarine's flavor often comes through better in a finished baked good as compared to natural butter. Baker's margarine is soft, but has excellent creaming properties.

Roll-in shortening is a harder fat than margarine, and is used in sweet doughs. Puff-pastry margarine is harder yet, and is used to produce croissants and Danish doughs. Shortening for puff pastries is added to dough by a process called booking. A layer of semi-soft margarine is spread across the center of a piece of sweet dough. Each side is folded to the center, forming a book. The dough is retarded (refrigerated) to firm up the fat. After cooling, the dough is rolled out and the process is repeated several more times. The finished dough has between 45 and 60 layers.

Fluid shortenings have some characteristics of plastic shortenings, but are pumpable. Fluid shortenings that produce finished products identical to those made with plastic shortenings have been developed. Fluid shortening are much more economical to transport, and reduce plant labor. In some applications, lower levels of fats can be used with fluid shortenings.

The bakers rack

English muffins, the first bread used for fast-food breakfast sandwiches, use both yeast and chemical leaveners, although yeast is the more important variety. English muffins require a specialty bread flour with absorption levels of 79% to 85%, plus 1% to 2% vital wheat gluten. Water, vinegar (contributing a slightly acidic flavor), yeast, salt, sugar, shortening, calcium propionate (mold inhibitor) and fungal protease complete the formula.

English muffins' coarse texture comes from intentionally over-mixing the dough. After the first proof, the dough is shaped into balls, rolled in cornmeal and proofed 30 additional minutes. A two-sided griddle that flattens the dough produces a golden brown appearance on the top and bottom. A chemical leavening agent, sodium aluminum phosphate, may be used to promote the formation of large air pockets when the dough contacts the hot griddle. Next, the muffins are cooled to ambient temperature, sliced or split, and packaged.

Biscuits, another popular breakfast-sandwich builder, are an example of a chemically leavened breakfast food with many variations. A basic biscuit formulation contains the following ingredients: soft wheat flour, shortening, sugar, salt, chemical leavening and NFDM. The dough is formed with minimal mixing, keeping gluten development to a minimum and maintaining a more tender texture. Softer wheat flours increase tolerance to over-mixing, while dextrose often replaces sucrose for a golden-brown surface.

The leaner and drier the biscuit formula, the shorter its holding time. In foodservice applications, biscuits that are held in a warming drawer or under a heat lamp can be improved by adding higher levels of fat and brushing the surface of freshly baked biscuits with liquid shortening to help seal in the moisture.

To produce a flakier biscuit, higher-melt-point fat flakes or chips are added as part of the shortening system. A harder fat creates pockets in the dough between starch and protein layers that are maintained when the fat melts. Replace the unflavored fat chip with a cinnamon- or blueberry-flavored chip and you have a completely new product. The flavored fat chips in biscuits might not be sweet enough to support these flavors, but the finished product can be sweetened by applying a powdered-sugar glaze.

Cheese presents another way to add excitement to an ordinary biscuit. Shredded cheese might work in the home-baked variety, but harsh industrial applications often require specially formulated ingredients to maintain texture and flavor. "We have several products that provide varying degrees of melt and texture for use in baked applications," says Max Maxwell, business development manager, emerging technologies, Kerry Ingredients, Beloit, WI. "Our Cheese 'm-Up particulates are cost effective, shelf-stable cheese-flavored particulates that are specially formulated for baked applications. There are also several types of KerryBITS that provide melting or identity-preserved cheese-flavored particulate options.">

Sweet starts

Luckily, we don't have to fire up the griddle or waffle iron when we want pancakes or waffles in a hurry, thanks to ready-made pancake and waffle products. Both contain flour, water, sugar, NFDM, partially hydrogenated shortening, eggs, salt and leavening. Flour provides the basic structure, while sugar provides flavor and some tenderization. Sugar also thins the batter, but if a sweeter pancake is desired, viscosity can be increased with a hydrocolloid. NFDM contributes flavor and improves surface browning, and oil is added for tenderization and mouthfeel. Egg yolks contribute flavor, color and some minor emulsification from their phospholipids. Egg white provides structure when its protein denatures during cooking. Salt is used as a flavor potentiator, and a double-acting leavening system provides a fine, even grain.

Pancake and waffle batters are mixed for a short time with no shear. The leavening system typically contains two acids, MCP and SALP, for example. When the batter is mixed, MCP reacts with soda at room temperature, but SALP does not react until it is exposed to higher temperatures. This two-phase leavening system builds in the tolerance needed for manufacturing, where there is usually some floor time before cooking.

Griddle temperatures range from 325° to 375°F; cooking time is approximately two minutes on the first side and one to one-and-a-half on the second side. These cooking times depend on the viscosity of the batter, the temperature of the griddle, and the desired degree of surface browning in relation to production line speeds. Dextrose often replaces some sucrose in pancake formulations to promote quicker surface browning.

Prepared frozen pancake batters for foodservice applications require three different leavening acids - two forms of MCP, plus SALP. Unencapsulated MCP produces carbon dioxide prior to freezing; encapsulated MCP, which reacts at 50°F or higher, ensures that the CO2 isn't lost during the freeze/thaw process. SALP solubilizes at higher temperatures, providing CO2 on the griddle.

Muffins are another frequent eat-on-the-run breakfast selection. Many consumers perceive them as a healthy alternative to fried eggs and bacon. While few muffin varieties are low in fat, they often contain healthful ingredients such as fruit, nuts and bran. However, the size of a typical muffin has grown from approximately 3 oz. to 6 to 8 oz., which negates most health benefits due to the amount of fat and calories consumed in one serving. The increased size also presents a unique set of challenges for the product designer - the formulas are sweeter, higher in fat, and the resulting texture is more like that of a high-ratio cake formulation.

Muffins are mixed gently to avoid loss of CO2 and development of gluten, which causes toughening of the texture and a product defect described as tunneling. To prevent this defect, avoid over-mixing, and ensure that the level of water or milk in the formula is at least 50% of the flour weight. If it is not possible to reduce over-mixing in production, replacing some of the flour with ingredients such as sugar, corn flour, whole-wheat flour or modified starch can have a similar effect by lessening the opportunity for gluten formation.

Cake doughnuts, another popular quick-breakfast item, are chemically leavened batters deposited in a ring shape into hot oil and fried. Leavening must react quickly enough in the oil to maintain the shape, but not continue to the point where tunneling occurs and the doughnuts burst. Excess oil absorption causes a greasy flavor, but a proper frying temperature and fresh oil minimize this defect. Carboxymethylcellulose has been shown to reduce oil absorption and improve adherence of dusting sugars or frosting.

Yeast-raised doughnuts and other yeast-raised, fried pastries are also a quick-grab favorite. These products are typically proofed twice, once as a dough, and once after cutting into the desired shape. Their less-cakey texture works well with fruit and creme fillings.

Many quick-breakfast products can be premade and frozen, delivering a finished product in a convenient form for both home and foodservice use. When freezing isn't an option, preservatives can extend shelf life. Sorbic acid or a solution of potassium sorbate can be added to doughs to prevent the growth of many common spoilage organisms. However, care must be taken with yeast-raised products, as these ingredients can negatively influence yeast fermentation. Another method for extending the shelf life of prepared, packaged baked breakfast foods is flushing the package with CO2 to discourage mold growth.

Good and fruity

Sweet goods, breakfast bars and toaster pastries, in both shelf-stable and frozen forms, use fruit fillings for flavor and sweetness. The type and amount of fruit depends on the required cost and finished-product characteristics and the desired labeling. The FDA requires at least 10% fruit or fruit juice in a product to make any labeling claims about fruit content.

Most fruit fillings are sweetened with a combination of corn syrup and HFCS, but other sweeteners can be used. For a shelf-stable product such as a toaster pastry, the sweetener system must help maintain a soft texture and contribute to a low water activity. This maintains a soft texture and minimizes both moisture migration and the opportunity for microbial spoilage. Formulators can look at alternative sweeteners such as sorbitol or even glycerin to promote these effects.

Most fruit fillings for baked products have a pH at or below 3.6 to inhibit mold growth. They may also be formulated with added preservatives, such as potassium sorbate. Fillings are brought to a boil and are gelled with pectin, corn starch or gums such as alginates, depending on the finished product application. Pectin is used for doughnut fillings or similar products that are not subjected to baking. Fruit fillings must remain pumpable at process temperatures, but if the filling is too hot, excessive moisture transfer occurs into the pastry crust causing sogginess and an unacceptable finished product.

Dried fruit such as raisins, dates and apples can be added to many baked products. Often these must be adapted to specific applications. For example, cinnamon-raisin biscuits typically use baking currants rather than regular raisins. Currants are smaller than raisins, giving more piece show per pound. Baking currants and raisins have higher moisture content than standard versions, which contributes to better eating quality in the finished product.

Some product designers may choose to use an engineered fruit piece. These can range from colored and flavored pieces of real fruit - dehydrated apples masquerading as peach bits, for example - to infused products or fruit bits. "Fruit bits in general give high-intensity flavor bursts, with different textures and colors," says Diane Carnell, assistant R&D manager, Kerry Ingredients. "They have price and stability advantages over fruit. Their traditional application has been in baked goods, where they can either be made to hold their integrity or be formulated to give a puddle effect like a jam or syrup. These bits can be used in batter applications, however, color bleed might occur in a reconstituted batter with excessive hold times.

"Fruit bits are very successful as flavor carriers in waffles and pancakes," continues Carnell, "where the mix is made and cooked without a time delay. We are also using our fruit particulates to carry dietary supplementation such as calcium, vitamins and protein."

The eggs come first

Eggs often appear as minor functional ingredients in baked products, but eggs scrambled or on a sandwich are one of the key foods eaten for quick breakfasts. Eggs provide essential nutrients and a high-quality source of protein.

Formulating eggs for frozen applications requires understanding the functional properties of eggs. The white, or albumen, portion makes up 60% of the egg's weight and contains approximately 15% protein. Egg white is mostly water and protein, plus a small amount of sugar and inorganic ions. The yolk is composed primarily of lipids, in the form of phospholipids, triglycerides and cholesterol.

Egg quality is particularly important when formulating a multi-component product using precooked eggs for frozen applications. There are four grades for shell eggs defined by the USDA: AA, A, B and C. The eggs receive their grade based on four quality factors: shell, air cell, white and yolk. As eggs age, the thickness of the white decreases. The decreasing viscosity correlates with a reduced ability to coagulate and form strong protein networks. This quality loss is a particularly important to convenience foods using precooked eggs.

Many frozen breakfast sandwiches contain an egg patty. When cooked eggs are subjected to repeated freeze/thaw cycles, the protein structure becomes less able to hold water, resulting in syneresis and a drier, tougher egg. Modified starches, gums, partially hydrogenated oils, and whey blends can reduce this problem. Oil improves mouthfeel and compensates for moisture loss, while hydrocolloids bind water and protein prior to cooking. Modified starch absorbs any free water from syneresis, and also helps maintain eating quality of the egg.

Scrambled eggs or egg patties may carry meat or vegetable particulates to mimic a specific dish such as a Denver omelet. Numerous options exist. For example, Maxwell recommends meat-flavored and savory bits, which offer several advantages over adding real meat. "You can eliminate the waste, fat, gristle and other undesirable inconsistencies that come with many meats and at times get amplified when they are processed into small pieces.

"Some of the meat-replacement options," continues Maxwell, "are available meat-free which provides the opportunity to process these breakfast items at a non-USDA facility as long as less than 2% meat goes into the final product. There is also the potential of appealing to the ever growing number of vegetarian and meat-reducing consumers across the U.S. and Europe."

Breakfast meats

Bacon, sausage and Canadian bacon are popular breakfast meats. Lean Canadian bacon easily becomes dry and tough, and is seldom seen in frozen entree applications, but is often used in foodservice breakfast sandwiches. The higher fat content of bacon makes it a more attractive, although relatively expensive, meat choice for breakfast foods; however, once it's cooked, it is more difficult to prevent breakage.

Frozen, fully cooked sausage is especially popular with processors and foodservice establishments because USDA regulations allow ingredient proportions to vary, and also allow the use of soy-based meat extenders. The formulas can be adjusted to optimize price and availability of meat. A typical frozen cooked sausage-patty formula contains beef, pork, turkey, water, often with either soy protein isolates or concentrates, salt, flavoring, HVPs and spices.

Al Egbert, technical service manager, ADM, Decatur, IL, explains that soy-protein isolates may be used at up to 2% or soy-protein concentrate at up to 3.5% in the finished formula. Soy proteins absorb up to three times their weight in water, providing good binding capacity during cooking. The binding capacity not only increases moistness, but can also decrease shrink.

Fat level of breakfast meats can be adjusted and even supplemented with partially hydrogenated vegetable oils. The saturation of beef, pork and turkey fats decreases respectively, so this can affect shelf life as well as health considerations. This also means that the least expensive meat, turkey, is more susceptible to oxidative rancidity.

Food scientists are coming up with other creative ways to improve the quality of precooked sausage links and patties. For example, the California Prune Board, Pleasanton, CA has experimented with adding dried plum puree to turkey/soy breakfast sausage. A level of approximately 3% helps bind water, increasing cooked yield and providing a moister mouthfeel. Researchers are also hoping that the high level of naturally occurring antioxidants found in plum puree might also have a beneficial effect on the sausage shelf life by reducing fat oxidation.

Putting it all together

Developing shelf-life parameters for single baked goods is almost child's play for an experienced food scientist compared to the complexity of frozen breakfast entrees and breakfast sandwiches.

Freezing is often the first choice for maintaining quality attributes of quick breakfast foods. It decreases the staling rate of baked goods compared to room temperature or frozen storage. Freezing also prevents further growth of microbes, although only insignificant levels of microbes are killed due to freezing, so GMPs are still very necessary. The tendency of fats to undergo oxidative rancidity is reduced due to low temperature and low light. Flavor transfer from ingredient to ingredient in entree packages is also reduced.

Higher-fat products such as biscuits, breakfast sausage and muffins freeze better because of reduced susceptibility to ice crystal damage. Higher-fat foods typically have lower moisture contents, but are perceived by consumers as moist. Using higher fat foods that are individually frozen, assembled and repacked without thawing reduces flavor and ingredient interactions.

Frozen storage is good, but not perfect. Soggy baked goods are almost expected when prepared in a microwave. Often a simple solution is dissipating free water during heating by venting or uncovering the entree.

When formulating multi-component breakfast foods - i.e. scrambled eggs, potatoes and sausage - the correct packaging needs to be identified as early as possible in the product development process to optimize product quality. Microwavable trays with partitions are available, but these usually cost more than a plain tray. Partitioned trays can reduce some product defects that occur during storage, but the product is more appealing when in a single tray that helps create the mental image of a plate with home-cooked food.

Fresh-made quality can be maintained in a processed product if it is quickly frozen, well packaged (low moisture and oxygen transfer) and is properly handled during storage and distribution. The reality of product design is that it is usually impossible to apply and optimize every aspect of bench-top samples to scaled-up products. A team approach from the beginning of design through to commercialization ensures the best overall results.

Successfully combining different product technologies to produce a wide variety of convenient breakfast options satisfies the changing needs of consumers, and puts a hot, delicious breakfast on the table, or in the hand, in a matter of minutes.

Susan McKinney, M.S., of Complete Food Systems, LLC, based in the Chicago area, provides consulting services to the food industry. Her specialization is a unique and creative approach to product formulations, fresh ingredient prototypes and competitive analysis projects. She can be reached at CompleteFoodSytm@aol.com.

• Photo: American Egg Board

• Photo: Kerry Ingredients

• Photo: California Prune Board

• Photo: USA Dry Pea & Lentil Council

• Photo: Nielsen-Massey Vanillas

© 2000 by Weeks Publishing Company

Used with permission from Food Product Design Magazine

Weeks Publishing Company

3400 Dundee Rd. Suite #100

Northbrook, IL 60062

Phone: 847-559-0385

Fax: 847-559-0389